PBF Technology in 3D Printing

What is PBF?

PBF, or Powder Bed Fusion, is a group of additive manufacturing techniques that utilizes thermal energy to fuse materials, typically powders, layer by layer. This revolutionary technology has transformed the landscape of 3D printing, enabling the creation of complex designs and structures that were previously unattainable with traditional manufacturing methods.

The Importance of PBF in 3D Printing

PBF plays a crucial role in various industries by providing significant advantages that include:

- Design Flexibility: PBF allows for intricate geometries and designs that are impossible with conventional techniques.

- Material Efficiency: It minimizes waste through its additive process, using only the required amount of material.

- Customization: Businesses can easily customize products to meet specific customer requirements.

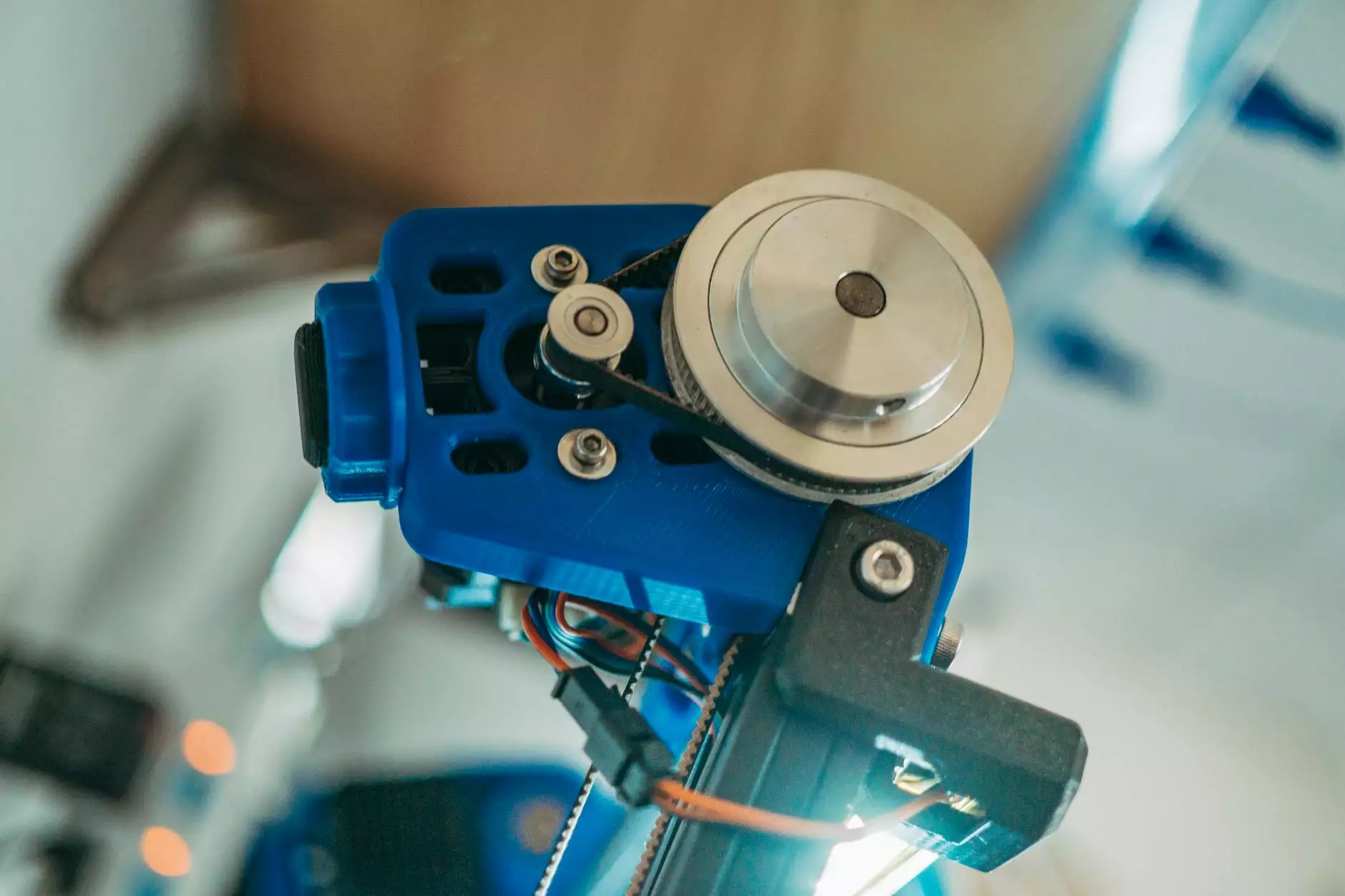

How PBF Works

The PBF process typically involves several steps:

- Preparation: A 3D digital model is created using CAD software.

- Layering: A thin layer of powdered material is spread across a build platform.

- Fusing: A heat source, usually a laser or electron beam, scans the powder bed to fuse it together according to the design.

- Repeating: The process is repeated layer by layer until the entire part is built.

- Post-Processing: Once constructed, parts are often subjected to additional finishing processes.

Benefits of PBF Technology

Implementing PBF technology presents numerous benefits to businesses, especially those in the manufacturing industry:

- Cost-Effectiveness: Reduces the overall costs associated with material waste and inventory management.

- Time Efficiency: Rapid prototyping enables companies to bring products to market faster.

- Enhanced Performance: Parts can be engineered for superior strength and weight characteristics.

Industries Benefiting from PBF Technology

PBF technology has significantly impacted various sectors, including:

Aerospace

The aerospace industry benefits immensely from PBF because it can produce lightweight yet robust components that meet stringent safety standards.

Medical

In the medical field, surgical instruments and implants can be custom-manufactured for individual patients, enhancing outcomes.

Automotive

Automotive manufacturers leverage PBF for rapid prototyping and the production of complex parts, optimizing performance.

Choosing the Right PBF Technology for Your Business

When it comes to integrating PBF technology in business operations, consider the following factors:

- Material Types: Different PBF techniques use various powders; choose one that suits your specific application.

- Production Volume: Assess whether you require high-volume production or low-volume, customized runs.

- Post-Processing Needs: Understand the additional processes required after printing to achieve the final product quality.

Future Trends in PBF Technology

As industries continue to evolve, so does the technology behind PBF. Notable trends include:

- Material Innovations: New materials are being developed, expanding the capabilities of PBF.

- Increased Automation: Automation in the PBF process increases efficiency and reduces human error.

- Integration with Other Technologies: PBF is being combined with technologies like AI to enhance its applications and efficiency.

Conclusion

The advent of PBF technology has revolutionized the field of 3D printing, offering unparalleled benefits across multiple industries. As businesses look to enhance their manufacturing processes, adopting PBF could be the step towards greater efficiency, customization, and cost savings. Infotron is at the forefront of this innovation, providing solutions that harness the full potential of PBF in the 3D printing landscape.